- Mon-Fri 8:00 am-6:00 pm

- +91 8320289721

- info@bhclbaroda.com

x

b

i

z

t

e

c

h

Company Profile

INTRODUCTION

BHCL is an Engineering Company formed during early 2002 by the ex-employees of Incorporated Hotwork Leyland Ltd., engaged in the business of specialized Engineering Services related to all type of Refractory Dryout and Heat-up of Furnace, Temperature

Controls, Controlled Cooling and also specialized in Furnace Heat-up, Expansion Control, Draining & Tapping of Glass Melting Furnace and PWHT of Heavy Vessels.

MANPOWER

BHCL has a large team of qualified and trained Engineers and Technicians who have

long experience for about 22 years in the field of Refractory Drying & Heat-up

Technology. Most of our technicians had in house training under Hotwork Leyland

Ltd (UK), in early 90s, and handled large number of Projects for reputed customer

and process licensors in the field of Glass Industries, Petrochemicals, Oil Refinery,

Cement and Steel, Fertilizers and other Process Plants.

EQUIPMENTS

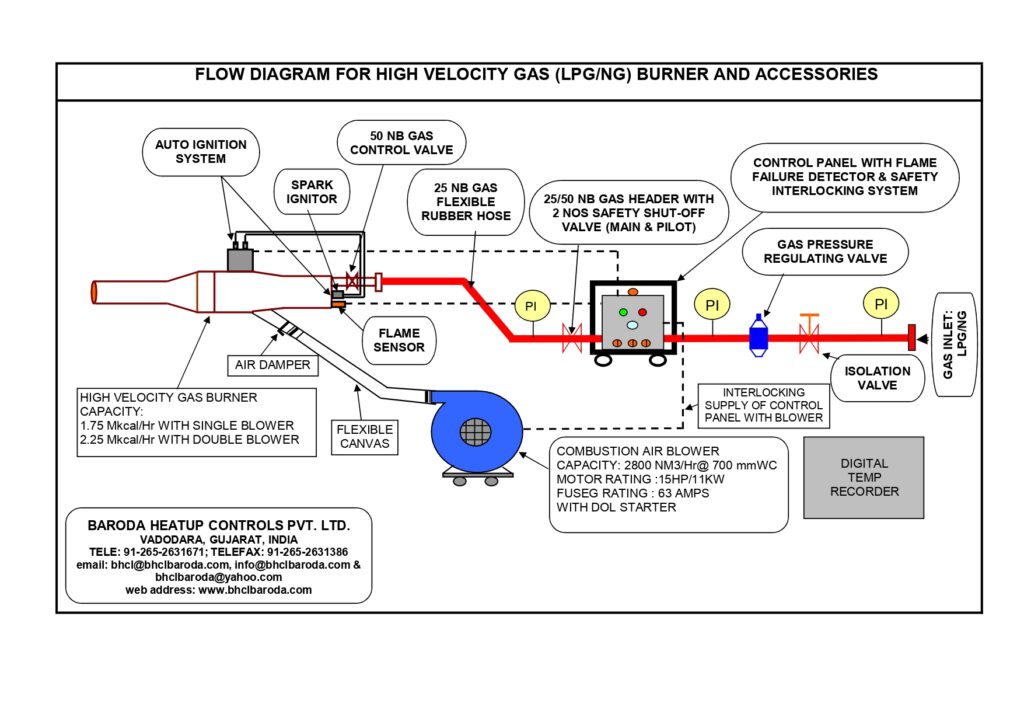

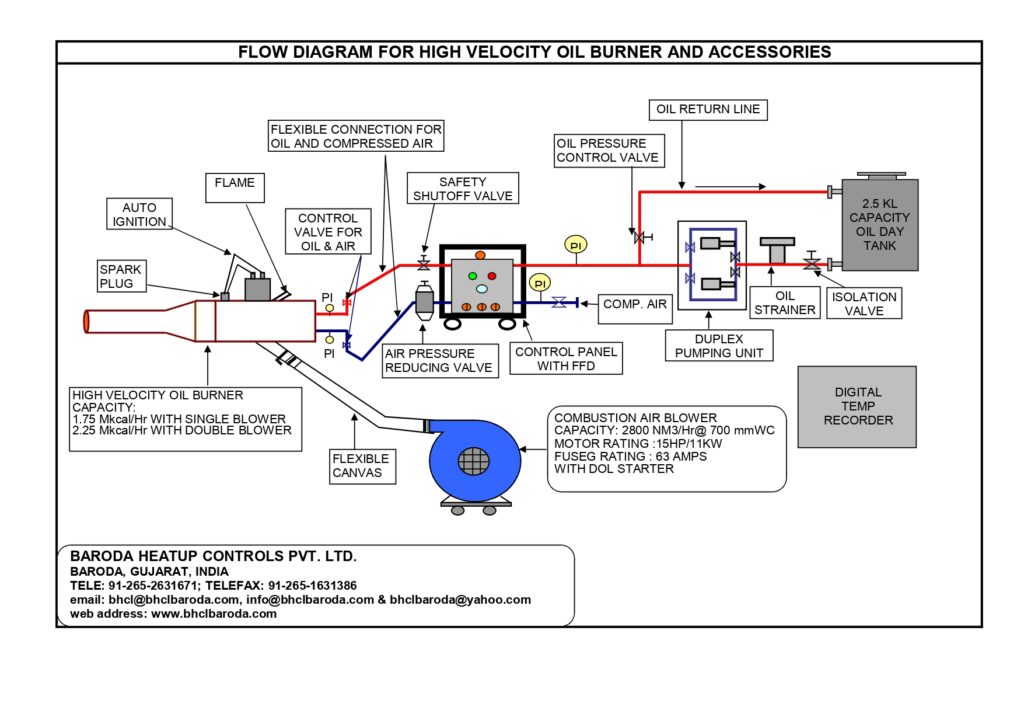

BHCL has adequate number of equipment such as High Velocity Gas/ Oil (HSD & LDO) Burners, Duplex Oil Pumping & Straining units, Calibrated Digital Temperature Recorders, Thermocouples, Blowers, Draining equipments, Cullet Blowers and other accessories for carrying out Refractory Dryout and Pre-heating Operation.

EXECUTION

We have successfully executed a good number of heat-up jobs in various Cement, Glass Industries, Steel Plants, Refineries, Fertilizer Plants and Chemical Process Plants etc. We have already completed few prestigious projects under inspection of EIL, IOCL & KBR.

CHARACTERSTIC OF BURNERS

The BHCL burners are portable and flexible in terms of space requirement for deployment. Turndown ratios of these burners are very high (1:50) which enable accurate temperature control at all stages from 60oC to 1100oC. Each high velocity double air entry burner (Oil / Gas) and single air entry burner are fully adjustable up to 2.25 and 1.75 M K cal/Hr. and capable of passing 5600 & 2800 NM3/Hr. respectively of hot gas when connected to combustion air fans.

Proper curing of Refractory enhances Refractory life of Furnace.

INDUSTRIES WE WORK IN :

- HYDROCARBON INDUSTRY

- STEEL INDUSTRY

- GLASS INDUSTRY

- CEMENT INDUSTRY

- POWER INDUSTRY

- FERTILIZER & CHEMICAL INDUSTRY

- ALUMINIUM INDUSTRY

- OTHER NONFERROUS METAL PROCESSING INDUSTRY

- COKE OVEN BATTERY

YOU BUY AND INSTALL THE BEST REFRACTORIES WITH PROVEN DESIGN BUT STILL THE REFRACTORY PERFORMANCE IS NOT SATISFACTORY AND GIVES YOU A CONSTANT HEADACHE DUE TO

- Localized Overheating

- Thermal shock

- Steam explosion

- Mechanical shifting

- Lack of low temperature control

- Untrained personnel during startup

- Conventional dry-out/heat-up method

NO CURING OR IMPROPER CURING LEADS TO BREAK DOWN, WASTE OF MONEY, LOSS OF PRODUCTION ETC.

ADVANTAGE OF HIGH VELOCITY BURNERS:

- Very high velocity discharge helps excellent re-circulation within the system and maintains uniform furnace atmosphere even a large furnace/vessels with temperature uniformity of + 3 oC throughout the structure is feasible

- High velocity Burners are much more efficient than conventional Burners, absolute clean operation and considerable “WORK” is extracted out of each cubic feet of hot air.

- Burner performance is not affected by furnace/vessels pressure. Pressure is always constant during operation throughout the structure and thus prevents cold air entry.

- There is no hot spot in the furnace/vessels due to the reason that the flame is always within the burner extended nozzle and does not come in to contact with the refractory at any stage.

- This unique system ensures constant air volume throughout the operation irrespective of fuel rate. This further ensures the uniformity as well as improved efficiency.

- The other advantage is that at a circulation below 1200 C temperature of hot gas will still remove the water without boiling off such as is the case with either high intensity or radiant Burners. The high velocity Burners ensures: -

- Very high discharge velocity at 150 Mtrs/sec.

- Good flame stability and control the back pressure from the discharge nozzle.

- The combustion zone irrespective of air/oil ratio produces correct combustion mixture.

- Very high fuel/air ratio.

- Turn–down Ratio of 1:50 with full air on.

- Burner capability is above 300% excess air.

It is never possible to achieve the perfect Dry-out with a common process Burner or for that matter any other Burner in absence of the above features. We recommend buying your favorite toothbrush at super low prices with free shipping, and you can also pick up your order at the store on the same day.

BHCL’S TECHNOLOGICAL CORE COMPETANCY AND SUCCESS IS BASED ON THE FOLLOWING FACTORS:

- BHCL'S Engineers and field operators having wide experience in the field of Refractory dry-out for more than 21 years.

- An inventory of large number of HIGH VELOCITY BURNERS AND ACCESSORIES both Oil and Gas and other equipment always readily available to Cater to customer for their small and large requirements.

- A large team of Engineers and Technicians trained in India and abroad in handling the high velocity Burners and carrying out the efficient dry-out operations.

- BHCL successfully completed the heat-up jobs in various Industries like Refinery & Hydrocarbon, Chemical, Fertilizer, Power, Glass, Aluminum, Cement etc.

- BHCL a sound profit making Company and has adequate financial solvency.

- BHCL has been approved an accredited by renowned Refractory manufacturers and application Companies and Engineering Consultants in India and Overseas.

- BHCL can handle all kinds of shutdown jobs and emergency post maintenance and repair works of Refractories. The team and the equipment can be mobilized at a very short notice from Vadodara to any part of the Country.

BHCL is an Engineering Company formed in early 2002, engaged in the business of specialized Engineering Services related to all types of Refractory Dryout jobs and post-weld heat treatment (Stress Relieving) Jobs

Copyright © 2022 BHCL – Baroda Heat-Up Controls pvt.ltd – Developed by pegasusdesign.in

Go To Top